Horizontal Pumps with mechanical seal

Standardized chemical pump CS

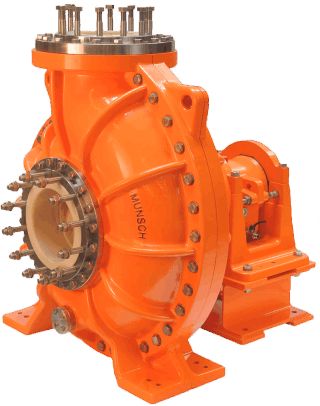

Armoured horizontal pump with mechanical seal

The armoured pumps of the NPC series are designed to meet chemical process industry standards and are ideally suited to pumping chemicals and solvents manufactured in back pull-out design.

The MUNSCH REA mechanical seal, specifically developed for non-metallic pumps, ensures maximum operating reliability and a long service life while being easy to assemble and repair

Materials:

The chemical pumps are available in PP, PVDF as well as in corrosion-resistant PFA for universal fluid compatibility.

Performance data

Pump capacity: up to 200 m³/h

Total differential head: up to 90 m

Operating temperature [t]: -20°C bis +180 °C

Operating pressure [p]: up to 16 bar

Solids content: up to 5 Vol.-%

Particle size: up to 5 mm

Diameter of discharge nozzle: DN 25 up to DN 65

Drive rating [P]: up to 30 kW

Applications

The CS-series pumps are the solution of choice for the safe pumping of fluids posing an environmental or health hazard such as acids, alkalis, solvents and chemically contaminated fluids in the presence or absence of solids.

Typical applications include the chemical and pharmaceutical industries, electrolysis plants, electroplating plants, the metallurgical and metal finishing industries. .

more Information / Application

Construction

Standardized chemical pump, process pump design with dimensions to EN 22858/ISO 2858;

Complemented by Size 40-25-125 and 40-25-160

Mechanical seals

The main construction material of the mechanical seal is silicon carbide. No other material offers better corrosion and wear resistance.

MUNSCH REA FS single mechanical seal:

Gleit- und Gegenring sind aus Siliziumkarbid; die Feder ist mit Fluorkunststoff ummantelt.

MUNSCH REA FS/D double mechanical seal:

Product-side stationary and rotating seal rings fabricated from silicon carbide, atmosphere-side stationary seal ring made of carbon; stainless steel spring.

Shaft sleeve:

Silicon carbide

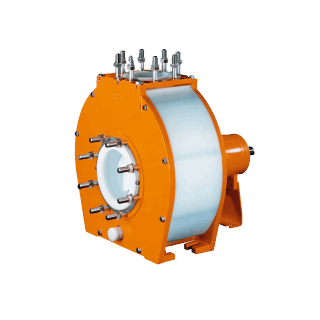

Standardized chemical pump CS-B

Armoured, close-coupled horizontal pump with mechanical seal

The armoured pumps of the CS-B series are designed to meet chemical process industry standards and are ideally suited to pumping chemicals and solvents manufactured in back pull-out design.

The MUNSCH REA mechanical seal, specifically developed for non-metallic pumps, ensures maximum operating reliability and a long service life while being easy to assemble and repair

Materials:

The chemical pumps are available in PP, PVDF as well as in corrosion-resistant PFA for universal fluid compatibility.

Performance data

Pump capacity: up to 90 m³/h

Total differential head: up to 60 m

Operating temperature [t]: -20°C bis +180 °C

Operating pressure [p]: up to 16 bar

Solids content: up to 5 Vol.-%

Particle size: up to 5 mm

Diameter of discharge nozzle: DN 25 up to DN 65

Drive rating [P]: up to 18,5 kW

Applications

The CS-series pumps are the solution of choice for the safe pumping of fluids posing an environmental or health hazard such as acids, alkalis, solvents and chemically contaminated fluids in the presence or absence of solids.

Typical applications include the chemical and pharmaceutical industries, electrolysis plants, electroplating plants, the metallurgical and metal finishing industries. .

more Information / Application

Construction

Close-coupled chemical pump design with dimensions to EN 22858/ISO 2858;

Complemented by Size 40-25-125 and 40-25-160

Mechanical seals

The main construction material of the mechanical seal is silicon carbide. No other material offers better corrosion and wear resistance.

MUNSCH REA FS single mechanical seal:

Gleit- und Gegenring sind aus Siliziumkarbid; die Feder ist mit Fluorkunststoff ummantelt.

MUNSCH REA FS/D double mechanical seal:

Product-side stationary and rotating seal rings fabricated from silicon carbide, atmosphere-side stationary seal ring made of carbon; stainless steel spring.

Shaft sleeve:

Silicon carbide

Standardized chemical pump NP

Horizontal pump with mechanical seal

Applications

The NP pump series is excellently suited to pumping tasks in the chemical industry, electroplating plants, metallurgical industries, steel and stainless steel pickling lines, evaporation and regeneration units, wet flue gas cleaning systems downstream of waste incinerators as well as in exhaust air scrubbing and industrial waste water treatment.

more Information / Application

Materials

The chemical pumps are available in PP, PE-UHMW as well as PVDF.

Performance data

Pump capacity:

up to 1200 m³/h

Total differential head:

up to 100 m

Operating temperature [t]:

-20°C up to +110 °C

Operating pressure [p]:

up to 10 bar

Diameter of discharge nozzle:

DN 25 up to DN 250

Drive rating [P]:

up to 200 kW

Construction:

Horizontal centrifugal pump, process pump design;

Casing and fitting dimensions to EN 22858/ISO 2858;

Complemented by size 40-25-125, 40-25-160, 250-200-400 and 300-250-400.

Mechanical seals

The MUNSCH REA mechanical seal, specifically developed for non-metallic pumps, ensures maximum operating reliability and a long service life while being easy to assemble and repair.

The main construction material of the mechanical seal is silicon carbide. No other material offers better corrosion and wear resistance.

MUNSCH REA F single mechanical seal:

Stationary and rotating seal rings fabricated from silicon carbide; the spring is encapsulated in fluoroplastics.

MUNSCH REA F/D double mechanical seal:

Product-side stationary and rotating seal rings fabricated from silicon carbide, atmosphere-side stationary seal ring made of carbon, stainless steel spring.

Shaft sleeve:

Fluoroplastics-coated stainless steel.